Vacuum chambers serve several vital purposes, from preserving specimens at specific temperatures to extracting moisture and gases from food products and even testing chemicals’ effects. The actual Interesting Info about tempered vacuum glazing.

Glass vacuum chambers are designed to withstand pressure for an extended period. Furthermore, they’re easier to clean than metal ones and can be attached with epoxy or superglue glue.

Vacuum chamber materials must possess low outgassing rates and be capable of withstanding bake-out temperatures, in addition to being compatible with process gases or materials used in the chamber. They also must withstand air, water, or abrasive particle contamination without suffering damage; several factors must be considered when selecting an ideal material, such as the thickness, resistance, and permeability of their vacuum chamber.

Vacuum chambers can be constructed from various materials, including metals, glass, and ceramics. Each has its advantages and disadvantages; glass and ceramics, in particular, make an excellent choice due to their incredible strength, low surface area, and easy cleaning processes, plus being highly heat resistant!

Borosilicate glass was traditionally the go-to material for vacuum chamber construction. Borosilicate is highly resistant to corrosion and abrasion while still being highly strong with a low thermal expansion coefficient, enabling its manufacture using various techniques such as welding or brazing in short amounts of time.

Stainless steel is another popular choice for vacuum chambers, as it is relatively cost-effective and easily machined. Furthermore, its corrosion resistance makes welding easier; although if vacuum levels reach very high levels, it is essential to consider recrystallization temperatures that determine whether welding can occur.

Other materials can also be used to build vacuum chambers, including refractory metals and nickel alloys with higher melting points that can withstand higher welding temperatures. They also protect from radiation and magnetic fields – however, in certain instances, machinability may be more important than its resistance against magnetism or radiation.

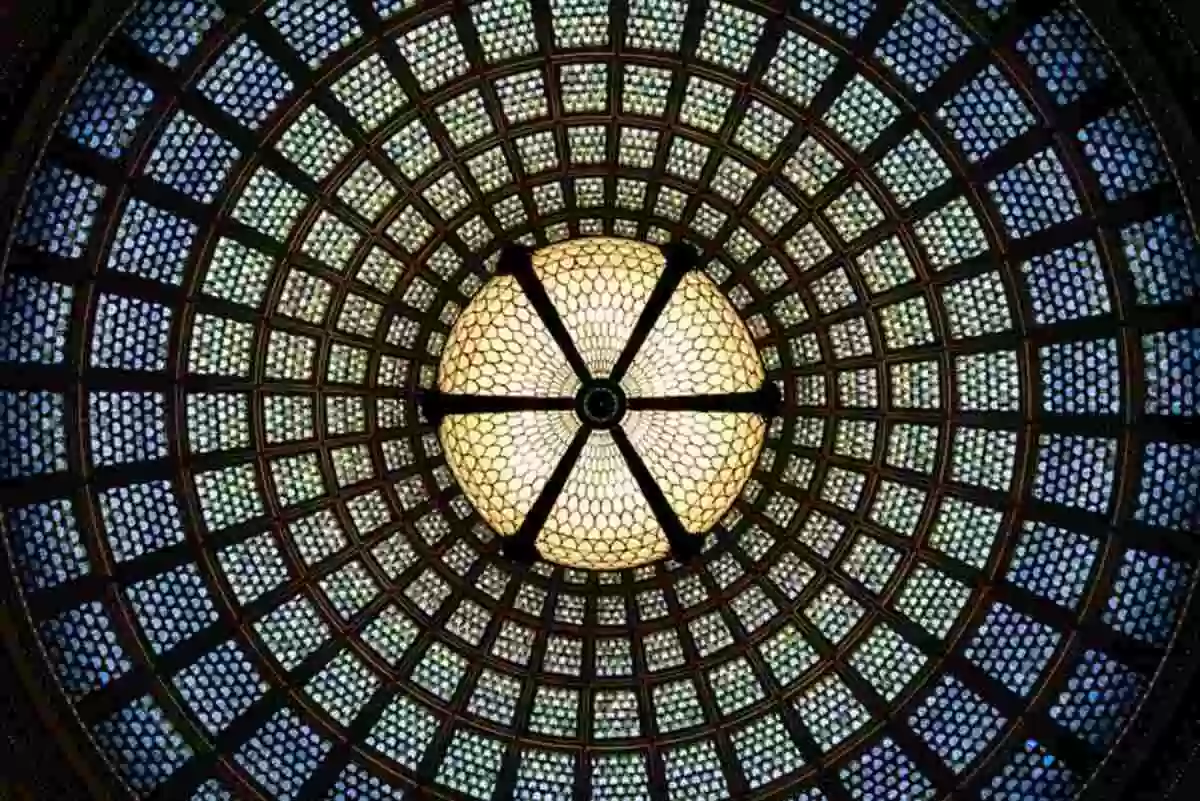

Observation windows are often made from borosilicate glass and coated with a particular substance to increase their transmissivity in visible and ultraviolet spectrums. The application method can range from chemical liquid to vapor deposition, offering greater accuracy and control.

Observation windows are an integral component of any high vacuum chamber system, enabling the direct observation of processes while providing real-time data collection without disturbing the ongoing operations. This enables faster and more accurate monitoring, leading to increased efficiency, improved quality, reduced energy consumption, and cost reductions for increased productivity in research & and development, aerospace manufacturing, refining facilities, and industrial manufacturing operations. These glass windows are used across industries, including R&D, aerospace manufacturing and refining, and industrial manufacturing operations.

Sight glasses can be constructed using various materials to optimize performance in visible or invisible spectrum ranges, depending on their application. Materials with low absorption tend to provide lower losses per thickness, while transparency can be further increased using anti-reflective coatings. Deciding upon an ideal material depends on both its intended use and the environment for the installation of the sight glass.

Sight glass assemblies must be airtight to preserve vacuum conditions and confine plasma. This can be accomplished using bonding or sealing methods that tightly join transparent material to metal, such as diffusion bonding – an effective solution for small gaps and high-temperature applications; however, it requires perfect axial symmetry of joints; otherwise, localized compression may result in lost vacuum in its vicinity.

Ideal Vacuum ISO-K HALO View non-illuminated windows are constructed using sapphire or quartz glass that provides excellent transmission rates in the UV and visible spectrums and features a stainless steel mounting flange suitable for UHV or XHV environments. Available in various sizes and shapes to meet your specifications.

Leaded glass viewport shields can be attached as “piggyback” shields to CF-type zero-length viewports of 1.33 to 8 inches in diameter to protect from harmful X-ray radiation while permitting clear visibility into a vacuum system. They are certified up to 2mm of lead shielding equivalence for safe usage and reach this threshold rating.

Vacuum chambers are used to safely test materials or apply finishes, from trying to apply finishes. To function effectively, they must operate at precise temperatures and vacuum levels while being compatible with their applications and conditions, such as gas composition, reactive species presence, and status of vacuum exposure, to prevent outgassing and contamination of their surrounding environment. Choosing suitable materials depends on variables like the exact gas composition, the presence of reactive species, and the level of vacuum exposure within the chamber.

Material selection for vacuum chambers should take into account both high temperatures and corrosion resistance. Stainless steel and copper are popular choices due to these qualities, though it’s important to remember they also come with some drawbacks, including being tricky to work with due to high vapor pressure levels; poor thermal conductivity (which may create issues) can present unique issues; and using these materials may increase manufacturing time as well as cost.

Joining methods for glass vacuum chambers include brazing, soldering, and welding. Depending on the application and desired performance requirements of a room for medical applications such as hospitals or pharmaceutical laboratories, specific joining methods must offer hermetic seals to protect from leakage and contaminants entering.

To enhance the quality of vacuum-chamber joints, innovative coatings and treatments are currently being created. These new developments will offer better thermal conductivity, radiation resistance, contaminant reduction, and decreased outgassing rates that will aid in creating stable vacuum environments.

One of the advantages of acrylic vacuum chambers over metal ones is their ease of repair via epoxy or glue, unlike metal chambers. Also, acrylic is non-flammable and heat-resistant, making it suitable for food processing applications and ovens. However, acrylic is fragile and will crack under concentrated stress; therefore, it should only be threaded when necessary and when selecting a screw size that suits it, as using any incorrect screw size could lead to cracks or crazes on its surface.

If you’re shopping for a quality vacuum chamber, look for one with an easy-to-read gauge that helps regulate pressure and temperature for your procedures. A sturdy structure capable of withstanding heat and pressure will help protect samples from contamination while prolonging their lifespan and reducing maintenance costs.

Vacuum chambers are essential in various industrial and laboratory processes, from degassing chemicals to distilling them. Pharmaceutical companies utilize them to make high-quality drugs, while food manufacturers use them to preserve samples and extend product longevity. Furthermore, vacuum chambers help remove moisture from raw materials, which could otherwise lead to damage and subsequent bacterial growth.

Remember when purchasing glass vapor chambers that they may become damaged during transport and shipping. Therefore, when receiving your shipment, it is wise to inspect for scratches or air pockets to determine any potential issues and contact the company so they can replace your chamber with an undamaged piece.

To keep your vapor chamber functioning at its optimal levels, it is suggested that you regularly use a lint-free cloth dampened with isopropyl alcohol or methyl ethyl ketone (MEK) to wipe down its interior surfaces and the lid of the vacuum chamber; this will prevent cross-contamination and extend the sensor lifespan.

When cleaning your glass vacuum chamber, be sure to use a cleaner that is non-abrasive and designed for stainless steel. Abrasive cleaners may cause etching inside the room, making removal very difficult. If you don’t have access to special cleaners, you may still use warm water with mild soap instead; remember to rinse both inside and outside of it after each cleaning session for optimal results!

Read also: Home Team Pest Defense: Protecting Your Haven From Unwanted Intruders

Have you ever looked down at your carpet and wondered if there’s a budget-friendly way…

Counter-Strike 2 (CS2) has elevated the thrill of case openings, captivating both seasoned CS:GO veterans…

Trying to sell a car online should be simple, but sometimes buyers lose interest fast.…

In the hustle and bustle of modern life, finding moments of quiet solace can feel…

You have probably heard on the importance of socializing dog after getting a puppy. It…

The mortgage industry is undergoing a significant transformation, driven by the rise of automation and…